Lubricating Oil Testing Service Market Overview

Lubricating Oil Testing Service Market size stood at USD 1.2 Billion in 2024 and is forecast to achieve USD 2.5 Billion by 2033, registering a 9.0% CAGR from 2026 to 2033.

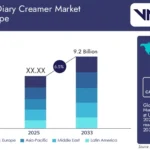

The lubricating oil testing service market is witnessing steady expansion globally, driven by the rising demand for high-performance machinery, stringent environmental regulations, and growing awareness around preventive maintenance. As of 2025, the global market size is estimated to be valued at USD 5.2 billion, and it is projected to grow at a CAGR of 5.8% over the next 5–10 years, reaching approximately USD 9 billion by 2035.

The core objective of lubricating oil testing services is to ensure that oils used in various industrial and automotive applications maintain their intended performance over time. As machines and engines become increasingly complex, precise monitoring of oil condition is essential for operational efficiency, safety, and longevity. This is fueling the adoption of advanced testing protocols such as elemental analysis, viscosity testing, contamination detection, and oxidation stability evaluation.

The market is significantly driven by the growth in the automotive, aerospace, manufacturing, marine, and power generation industries, which rely on lubricants for their critical operations. Regulatory frameworks in both developed and emerging economies are emphasizing pollution control and waste management, necessitating regular testing of used oils before disposal or recycling.

In recent years, technological advancements have reshaped this market. Digitalization and real-time monitoring systems have enabled faster and more accurate diagnostics. Automated testing instruments, integration with IoT-enabled condition monitoring systems, and the application of data analytics are making oil testing services more predictive and cost-effective. These innovations are fostering the transition from reactive to preventive and predictive maintenance models.

The market is also being influenced by sustainability trends. With growing environmental concerns, there is increasing scrutiny of lubricant composition and usage. Industries are now more invested in prolonging lubricant life cycles through precise analysis, thereby minimizing environmental impact and reducing operational costs.

Moreover, the rise of electric vehicles (EVs) introduces new dynamics. Although EVs use fewer lubricants than internal combustion engine vehicles, the lubricants they do use—especially in cooling systems and drivetrains—require specialized testing. This diversification in lubricant types is creating new opportunities for testing services tailored to non-traditional applications.

Overall, the lubricating oil testing service market is poised for consistent growth, supported by industrial expansion, digital transformation, and sustainability imperatives. Emerging economies, in particular, offer substantial untapped potential due to the rapid industrialization and increasing machinery deployment across sectors.

Lubricating Oil Testing Service Market Segmentation

1. By Service Type

-

Routine Testing

Routine testing services include fundamental checks such as viscosity, acid number, water content, and base number analysis. These services are performed regularly to monitor the lubricant’s health and suitability for continued use. They help detect early signs of degradation or contamination and are essential for ongoing maintenance schedules in automotive fleets, industrial systems, and marine engines. Routine tests are typically standardized and form the backbone of most condition monitoring programs. -

Advanced Diagnostic Testing

Advanced testing involves more complex assessments like FTIR spectroscopy, ferrography, elemental analysis via ICP, and RULER (Remaining Useful Life Evaluation Routine). These are used to diagnose the root causes of lubricant failure or machine wear. These services are more prevalent in critical machinery where the cost of downtime is high. Advanced diagnostics are increasingly integrated into predictive maintenance frameworks and are gaining prominence as industries prioritize performance optimization.

2. By End-Use Industry

-

Automotive

Automotive applications remain the largest consumer segment for lubricating oil testing, especially in commercial fleets and public transport systems. Engine oil analysis ensures vehicles operate efficiently, reducing fuel consumption and emissions. The proliferation of heavy-duty and light commercial vehicles globally continues to bolster this segment’s demand. -

Industrial Machinery

Industries such as manufacturing, construction, mining, and food processing heavily depend on lubricants for smooth mechanical operations. Lubricating oil testing is vital for monitoring wear metals and contamination levels, thereby extending the life of machines and preventing production downtime. Industrial users often deploy in-house testing kits or partner with specialized labs for continuous monitoring. -

Energy & Power Generation

Gas turbines, wind turbines, hydroelectric systems, and backup generators all require high-performance lubricants. Oil condition monitoring in this sector is essential due to the high costs associated with equipment failure. Testing ensures lubricant integrity under extreme thermal and operational conditions, making this a high-value application segment. -

Marine & Aerospace

Lubricant testing in marine and aerospace sectors focuses on precision and reliability. These sectors often operate in challenging environments, where lubricant performance is crucial for safety and regulatory compliance. Due to higher operational risks, these industries typically rely on advanced testing services tailored to meet stringent international standards.

3. By Testing Location

-

On-Site Testing

On-site services enable real-time analysis using portable devices and kits, allowing operators to make immediate decisions based on current oil conditions. This method is preferred in remote or mission-critical locations like mines, ships, and construction sites. On-site testing is gaining momentum due to its speed and growing availability of accurate, user-friendly devices. -

Off-Site Laboratory Testing

Off-site testing involves sending oil samples to centralized laboratories for comprehensive analysis. It provides more accurate and detailed reports using sophisticated instrumentation that may not be available on-site. This method is prevalent for annual inspections, in-depth diagnostics, and regulatory audits, and is often favored by organizations with formal maintenance strategies.

4. By Testing Parameter

-

Contamination Testing

This includes detection of water, dirt, fuel dilution, and coolant presence. Contamination is one of the primary causes of lubricant failure, so its early detection is critical. Modern techniques use infrared, particle counting, and Karl Fischer titration for precise results. -

Chemical Property Testing

This evaluates acidity, oxidation, additive depletion, and base number changes. Monitoring these properties ensures the oil retains its lubricating and protective capabilities. Chemical degradation can lead to corrosion and increased friction, so timely interventions are vital. -

Wear Debris Analysis

Wear testing identifies metal particles suspended in the lubricant, which are indicators of mechanical wear. Techniques like ferrography and atomic emission spectroscopy are used. This analysis is essential for determining the condition of gears, bearings, and internal engine components. -

Physical Property Testing

Tests such as viscosity, flash point, and pour point fall under this category. These properties influence lubricant flow, temperature tolerance, and fire risk. Variations in these parameters can signal contamination or chemical changes, prompting immediate corrective measures.

Conclusion

The lubricating oil testing service market is evolving into a critical component of industrial maintenance and asset management strategies. As industries strive for higher efficiency, lower environmental impact, and extended equipment life, the importance of regular and precise lubricant testing cannot be overstated.

The next decade will likely witness deeper integration of digital tools, AI-driven diagnostics, and remote sensing technologies in oil testing services. Moreover, the growing focus on sustainable practices and the rise of electric and hybrid machinery will redefine lubricant formulations and their testing protocols.

Players in this space must adapt to the changing landscape by offering customized, real-time, and data-centric solutions. Emerging markets, especially in Asia-Pacific, Latin America, and Africa, present fertile ground for expansion, fueled by industrial growth and increasing regulatory scrutiny. The lubricating oil testing service market is not only a support function but is steadily becoming a strategic necessity across industries.