Market Overview (Current Size, Value & Growth Projection)

The Nozzle for Injection Molder market is at a strategic growth inflection point—driven by polymer demand, industry automation, sustainability pressures, and regional manufacturing shifts. With estimated CAGR reaching 6–8%, the global market is set to nearly double by 2032. Innovators investing in smart/nozzle technology and targeting sustainable, high-precision applications stand to capture outsized market share. Meanwhile, cost and labor constraints present challenges for smaller producers—but also opportunities for adaptive solutions, service offerings, and regional expansion.

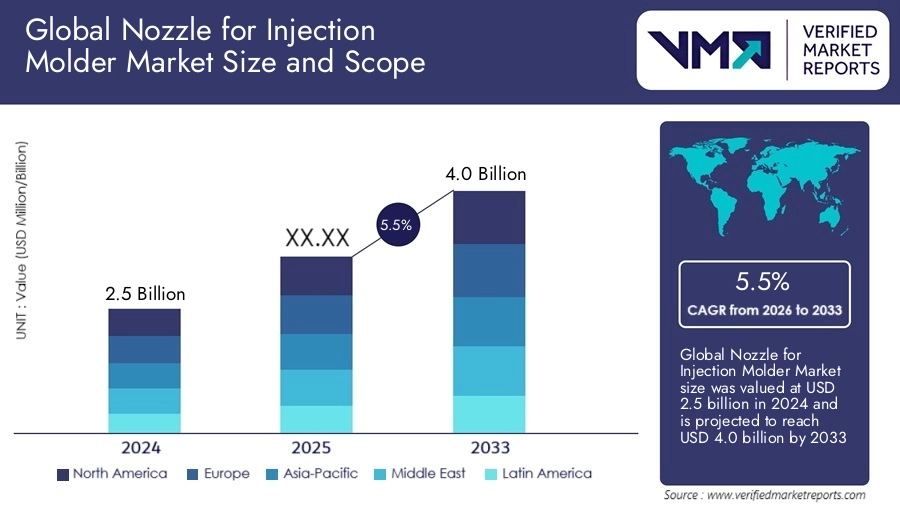

📊 Current Market Size & Forecast

-

2022: Valued at approximately USD 1.15 billion grandviewresearch.com+8verifiedmarketreports.com+8marketresearch.jp+8

-

2023: Estimates place it around USD 1.2 billion

-

2024–2030/2032:

-

Forecasts range from USD 1.80 bn by 2030 (CAGR 6.4%) cervicornconsulting.com+4verifiedmarketreports.com+4dataintelo.com+4

-

To USD 2.4 bn by 2032 (CAGR 7.5%) marketresearch.jp+13dataintelo.com+13dataintelo.com+13

-

A consensus estimate places the CAGR between 6–8% over the next decade.

🛠️ Key Growth Drivers

-

Increasing Demand for Plastic Components

-

The automotive, electronics, medical, packaging, and consumer sectors are continuing to fuel demand—seeking lightweight, precision-engineered parts arxiv.org+15verifiedmarketreports.com+15dataintelo.com+15reddit.com+1dataintelo.com+1.

-

-

Adoption of Advanced Nozzle Technologies

-

Steady growth in hot runner systems, valve-gate nozzles, multi-channel, and mixing nozzles—boosting mold precision, cycle times, and material uniformity reddit.com+10verifiedmarketreports.com+10marketresearch.jp+10.

-

-

Industry 4.0 & Automation Trends

-

Smart nozzles with sensors, IoT-enabled systems and ML-based QC/optimization frameworks are increasingly embraced arxiv.org.

-

-

Sustainability & Recycled Material Use

-

Rising use of recycled polymers boosts demand for optimized nozzles (mixing, anti-defect) verifiedmarketreports.com+8globalgrowthinsights.com+8precisionbusinessinsights.com+8.

-

-

Regional Manufacturing Shifts

-

Asia-Pacific dominates (38%+ market share in 2023); North America (22%), Europe (25%) follow reddit.com+8dataintelo.com+8globalgrowthinsights.com+8verifiedmarketreports.com. Shifts from China to India also create new manufacturing hubs reddit.com.

-

⚠️ Market Constraints & Challenges

-

High Upfront Cost & CapEx Barrier: Advanced nozzles (hot-runner, valve-gate) are costly—an adoption barrier for SMEs .

-

Raw Material & Quality Variability: Inconsistent nozzle performance if subpar materials used; rigorous QC required verifiedmarketreports.com.

-

Technological Pace & Obsolescence: Rapid innovation cycles require continuous R&D investment .

-

Skilled Workforce Shortage: Rising automation demands specialized engineers—strained by labor gaps .

🌱 Opportunities Ahead

-

Eco‑friendly & Recycled Material Optimization: Nozzle redesign for bioplastics, recycled material influx precisionbusinessinsights.com+3globalgrowthinsights.com+3verifiedmarketreports.com+3.

-

Customized Nozzles for 3D Printing & Niche Applications: Rise of hybrid production technologies en.wikipedia.org+8verifiedmarketreports.com+8dataintelo.com+8.

-

Smart Manufacturing Tools: ML- and DRL-powered injection optimization, predictive maintenance, real-time quality control integration arxiv.org.

-

Regional Manufacturing Expansion: Relocation to India, Mexico, Southeast Asia—driving local injection molding demand dataintelo.com+5reddit.com+5reddit.com+5.

🔮 Future Outlook

The nozzle market is forecast to double by 2032, propelled by polymer demand, automotive electrification, manufacturing automation, sustainability, and reshoring trends. Future innovation avenues include multi‑material mixing nozzles, sensor-embedded hot runner systems, and AI-driven QC/optimization frameworks integrated into Industry 4.0 lines.

2. Market Segmentation (Each ~200 words)

I’ve broken the market into four key segmentation categories: By Type, By Material, By Application, and By End‑User.

A. Segmentation by Nozzle Type

1. Straight (Open) Nozzles

-

Traditional, cost-effective design: molten plastic flows unabated. Broadly used where precision is less critical, e.g., packaging, consumer parts.

-

Benefit: simple design, low maintenance.

-

Limitations: potential for drooling, less control over flow—makes them less suited for high-precision or clean mold applications.

-

Market outlook: good share in low-cost production, but growth overshadowed by advanced designs dataintelo.com+3dataintelo.com+3precisionbusinessinsights.com+3.

2. Shut-off Nozzles

-

Equipped with a needle or valve to prevent drool and stringing between cycles.

-

Types: self-controlled (spring-needle) and externally actuated en.wikipedia.org.

-

Used in automotive, medical, and cleanroom settings where precision and leak prevention matter.

-

Market share strong (~28%), likely to grow as cleanliness and waste-control demands increase .

3. Hot Runner Nozzles

-

Mold-side heated channels keep plastic molten up to the gate; no cold runner waste.

-

Advantages: shorter cycle times, reduced scrap, better repeatability.

-

High adoption in auto, electronics, packaging. Asia‑Pacific hottest growth region (CAGR ~9.3%) verifiedmarketreports.com+1dataintelo.com+1.

-

They represent ~18% of nozzle market currently industrytoday.co.uk+2dataintelo.com+2marketresearch.jp+2.

4. Multi-Channel & Specialty Nozzles

-

Include valve-gate nozzles, multi-tip designs, mixing nozzles.

-

Valve-gate: equivalent to multi-point shut-off—precise control per cavity.

-

Mixing nozzles: blend colorants/additives evenly, reducing defects (~30% fewer defects; enhanced properties) .

-

Growing fast in medical, electronics, micro-molding niches.